Price: $24,500 See Monthly Payments

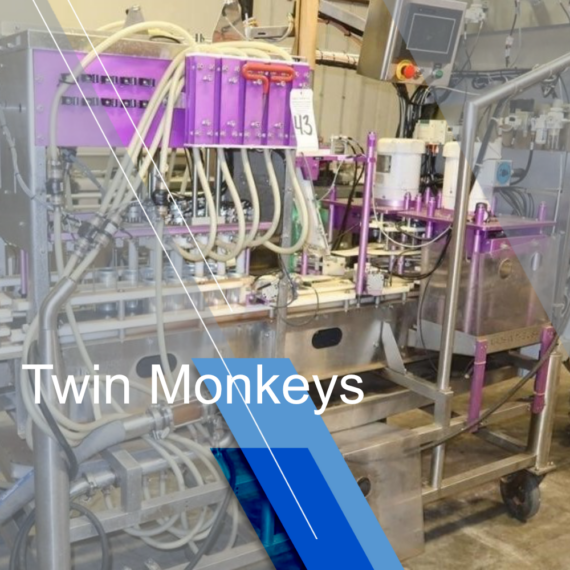

Fully automated canning system designed for beverage packaging.

Capabilities

Fully automated operation from empty can infeed to finished can outfeed

Quick changeover between 12 oz and 16 oz cans

Other can sizes available by specification

Lids placed on foam

Adjustable timers for all system functions

Designed for ease of maintenance

CIP/SIP capable fill system

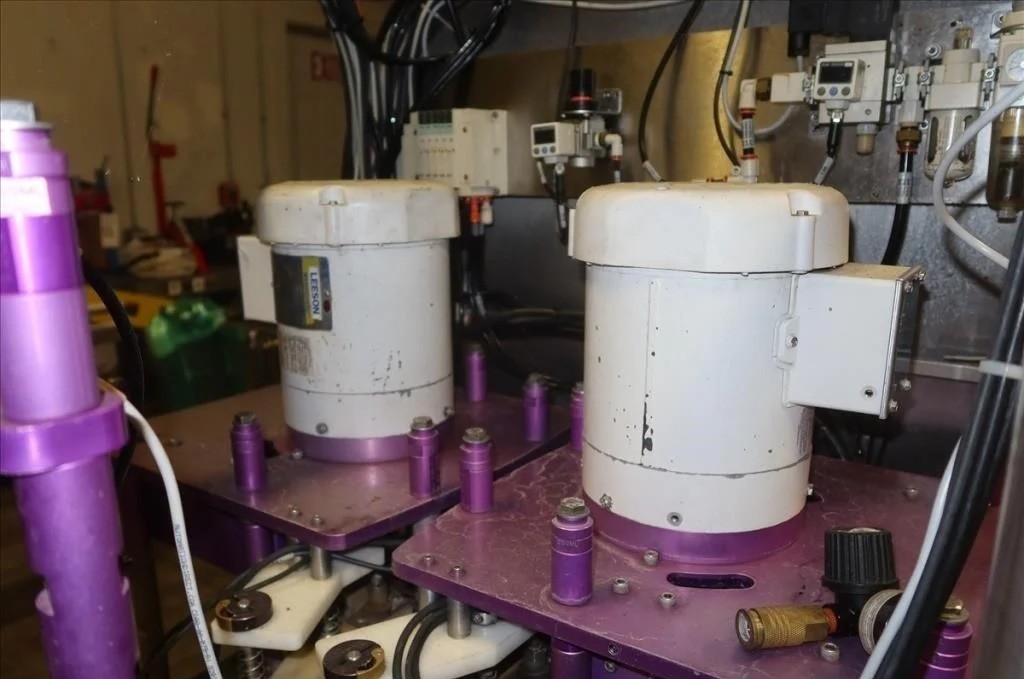

Filling & Seaming

Automated tank pressure controller for consistent fill and foam

Fill level repeatability: ±2 grams

Cam-less wedge seamer (patent pending)

No cams, reduced maintenance

Consistent and repeatable seams

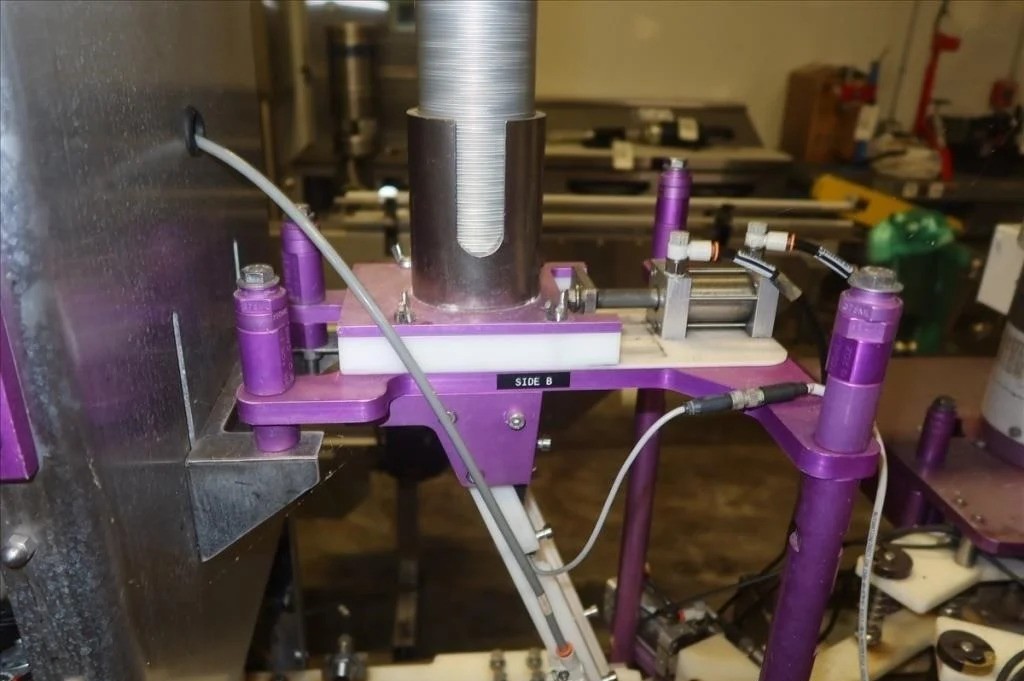

Lid applicator with integrated CO₂ blanket generator

Individual fill head foam and fill level adjustment

Oxygen Reduction Features

Closed fill tubes prevent air re-entry between fill cycles

Pre-fill purge station removes air before filling

Short transfer path from fill to seam

CO₂ blanket applied when lids are placed on foam

Adjustable foam and fill levels per fill head

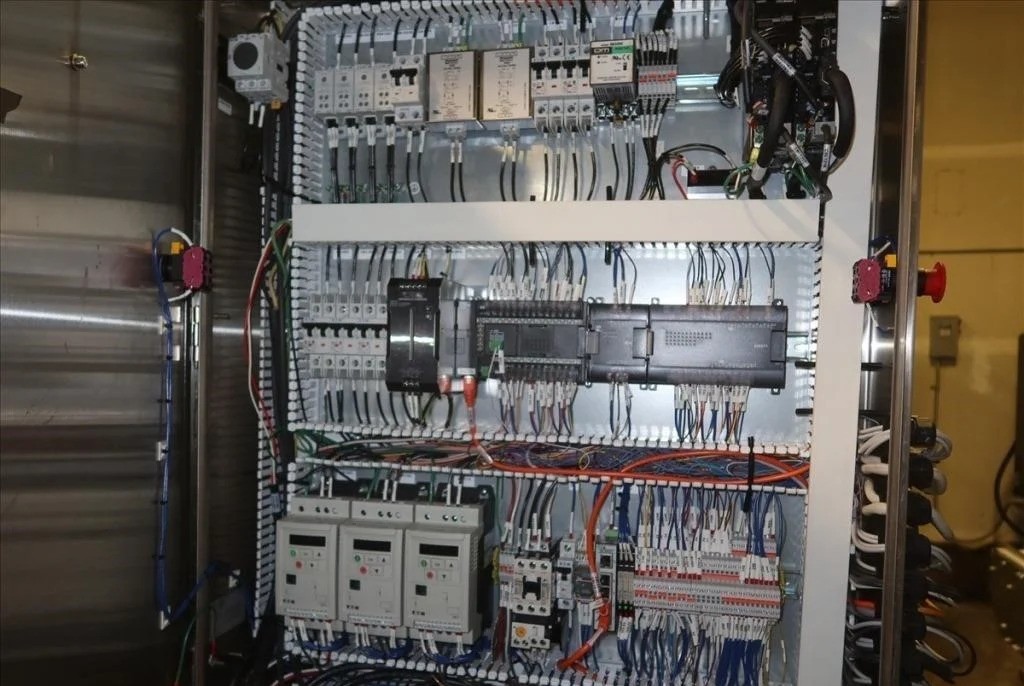

Controls & Cleaning

Color touchscreen operator interface

Integrated washdown systems for cleaning

Configurable layouts: inline, right-turn, or left-turn

Utilities Required

Electrical: 208–240V, single phase

Compressed air: 90 psi, 2.2 CFM (4.5 CFM at 80 cans/min)

CO₂: 20 psi, 1 CFM

Specifications

Throughput: 40 or 80 cans per minute

Standard can sizes:

12 oz (355 ml)

16 oz (473 ml)

Canner dimensions: 82” L × 36” D × 78” H

Rinser dimensions: 60” L × 22” D × 49” H

Weight: Approx. 950 lbs

Construction: 304 stainless steel and anodized aluminum