Price: $75,000 See Monthly Payments

10BBL BREWHOUSE w/20BBL HLT, 4 x 20BBL FERMENTERS, 1 x 20BBL BRITE TANK, CIP CART, KEG FILLER, GLYCOL CHILLER, GRAIN MILL, TRANSFER PUMP, & RITE BOILER – Sold as Package or Separately. In use and operational (since 2022), with over 24 award winning beers produced.

10BBL 2 VESSEL BREWHOUSE

- Platform positioned between BK/WH and MLT

- Non-slip walking surface c/w ladder and railing

- 7” touch screen PLC on Brew Deck ◦ Displays Mash in/Sparging flow meter rate and total

- Lauter and Whirlpool pump control

- Displays MLT and BKW temperatures

- Visual and audible alarm

- Valves are sanitary, butterfly, manually operated type

- H2O mixing station with thermometer in central location

- H2O outlet, 1.5″ tri-clamp

- 0.75 hp mash pump, sanitary, open impeller, 1750 RPM

- 2 hp wort pump, sanitary, open impeller, 3600 RPM

- Self-standing airless grant

- Heat exchanger to be sized according to local conditions

- Heat exchanger outlet with O2 stone, sight glass and thermometer

- Control panels contain pump controls, digital temperature for BK/W and MLT, and all brewhouse accessories

- All valves and tubing throughout brewing system are included

- All hard piping throughout brewhouse included

- All connections are TRC clamps

- Dual inline hop strainer

- Tank Lighting

RAKE SYSTEM (NON LIFTING)

- Unique design allows to successfully cut the bed and, at the end of the production, to remove the grain by changing the position of the wings.

- Heavy duty system, all in stainless steel

- Consists of a series of horizontal and vertical blades to cut the grain bed

- Variable rotation speed (mechanical speed adjustment)

10BBL MLT

- Design capacity: grain bed of 10″-14″ for optimum extraction

- Material: 304 stainless steel shell, 4A finish, 2.5 mm thick

- Conical top sloped at 27. complete with manway 400 mm diameter, 3mm thick

- Conical bottom sloped at 4., 3 mm thick

- Side wall: stainless steel clad, 2 mm thick

- High density insulation, 2”

- Stainless steel adjustable legs for tank leveling

- Steam dimpled jacket positioned on side of lauter tun

- Total discharge 3″ complete with valve

- Thermowell for probe positioning

- Vorlauf re-entry port, 1.5″, positioned at 150.

- Multiple equidistant outlets culminating in the manifold

- Gooseneck assembly to prevent vacuum conditions or airless grant

- Manometer for reading screen pressure differential

- Mashing and sparging spray ball on the extended arm

- False bottom screen 0.7 mm, in sections for easy removal

- Side manway, rectangular outside opening, for the discharge of the spent grain

- CIP cleaning on 1.5” inlet 2″ double elbow exhaust vent

- Grist hydrator, complete with manual gate

- Underlay spray system

10 BBL WHIRLPOOL

- Material: 304 stainless steel shell, 4A finish, 2.5 mm thick

- Conical top sloped at 27. complete with manway, 300 mm diameter (12”)

- Conical bottom sloped at 6., 3 mm thick

- Stainless steel clad, 2 mm, on side and bottom

- High density insulation, 2”

- Steam dimpled jacket, positioned on the side & bottom of kettle

- Stainless steel adjustable legs for tank levelling

- Total discharge 3”, complete with valve

- Off-set wort outlet, 2”, complete with valve

- Tangential wort inlet, 1.5” x 1”, to create whirlpool effect for trub separation

- CIP spray ball on 1.5” inlet

- Thermowell for probe positioning

- Water inlet, 1.5”

- Exhaust outlet, 6”

- Supplied with dipstick and ladle

- Sight gauge level indicator

- Overboil protection with acoustic alarm

20 BBL HLT

- Material: Stainless steel shell, 304/4A finish, 2 mm thick

- Conical top sloped at 10., complete with manway

- Conical bottom sloped at 10., 2 mm thick

- Stainless steel clad, 2 mm thick

- High density insulation, 2”

- Stainless steel adjustable legs

- Dimpled jacket positioned on the side of vessel

- Dual scale thermometer, with thermowell

- Thermowell for probe positioning

- Sight gauge level indicator

- Hard piping between tank and SERVING PUMPS FOR THE HLT (pump operates on demand)

- Stainless steel re-circulating pump, high pressure, 3500 RPM

- Pump outfitted with extra outlet and inlet for other use

- Complete with Buffer pressure tank, auto pressure switch & check valve

- All pump wiring and switches

FOUR 20 BBL JACKETED FERMENTERS & ONE 20 BBL JACKETED BRITE

- Operating pressure: 14.9 psi maximum

- Stainless steel shell, 304/4A finish, 2.5 mm thick

- Domed top, 3 mm thick

- Conical bottom, 2.5 mm thick (60 degree cone)

- 2 dimpled glycol jacket positioned on the full length of the shell maximizing efficiency

- 1 dimpled glycol jacket positioned on the cone of vessel

- High density insulation, 2”

- Stainless steel clad, 1.5 mm thick, on side of vessel (full welded)

- Stainless steel clad, 1.5 mm thick, on cone of vessel (full welded)

- Stainless steel legs with adjustable floor pads

- Side manway, “Shadowless”

- Dual scale thermometer with thermowell

- Thermowell for probe positioning

- Sampling valve, “Perlick” type

- Racking outlet, 1.5″ TRC

- Total discharge, 2″ TRC

- Vacuum/pressure relief valve, 2″ tri-clamp

- 1” NPT fitting for glycol inlet/outlet

- CIP arm, 1.5″, with removable spray ball assembly

- #1 – CO2 valve, .” complete with pressure gauge

- #2 – Lifting lugs

- Racking arm 6” Hop Ports Temperature Controllers

ECONO MILL WITH EXPLOSION PROOF MOTOR

The mill has a capacity of approximately 1200lbs/hr. Unit comes with hopper, motor mount, stand, magnet and drive pulley.

- Heavy duty unit, complete with safety guards

- Econo roller mill

- Length: 6” Diameter: 8”

- 1.5 HP / 3 PH explosion-proof motor

FLEXAUGER-BOOT FLEX AUGER

- Heavy duty unit

- Single 30 degree boot assembly

- 30 foot PVC direct drive (1/2 hp) flex auger system which includes:

- ◦ 3-10’ PVC tubes

- ◦ 2-45 degree PVC elbows

- ◦ auger

- ◦ chain for hanging

- ◦ mechanical switch

MOBILE TRANSFER PUMP

- Tri-clover pump, full sanitary design

- 1.5” TRC connections

- On trolley with wheels

- Can be utilized as a filter pump

- All electrical included

Kegfiller KEG FILLER

- Four keg filling manifold

- Stainless steel construction

- Pressure gauge

- Sankey keg taps

DUALTANK-CIP DUAL TANK CIP CLEANING SYSTEM

- Stainless steel construction •

- Heavy duty frame with wheels

- #2 – 250 L tanks with manway, with heating element

- High pressure stainless steel pump

- Valves are sanitary, butterfly type

- All piping and electric included

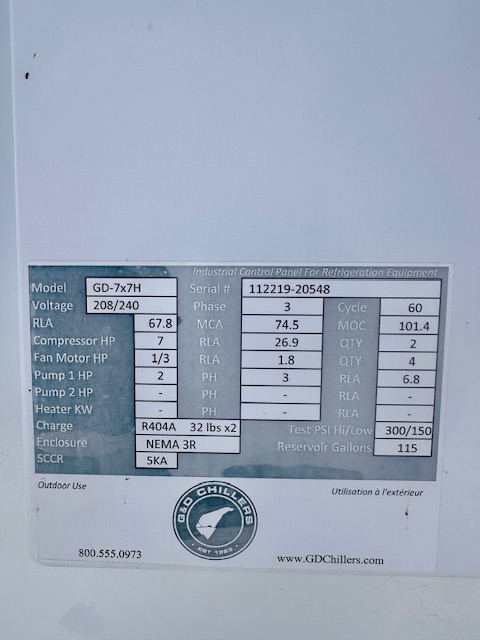

G&D 7×7 MK-18A-160 GLYCOL CHILLER

- Power Supply: 230 V / 3 Phase / 60 Hz

- 102,092 BTU/hr. @ 30Åã F •

- 65 GPM @ 25 psi. •

- 2 HP GLYCOL PUMP 1.5” FPT connections

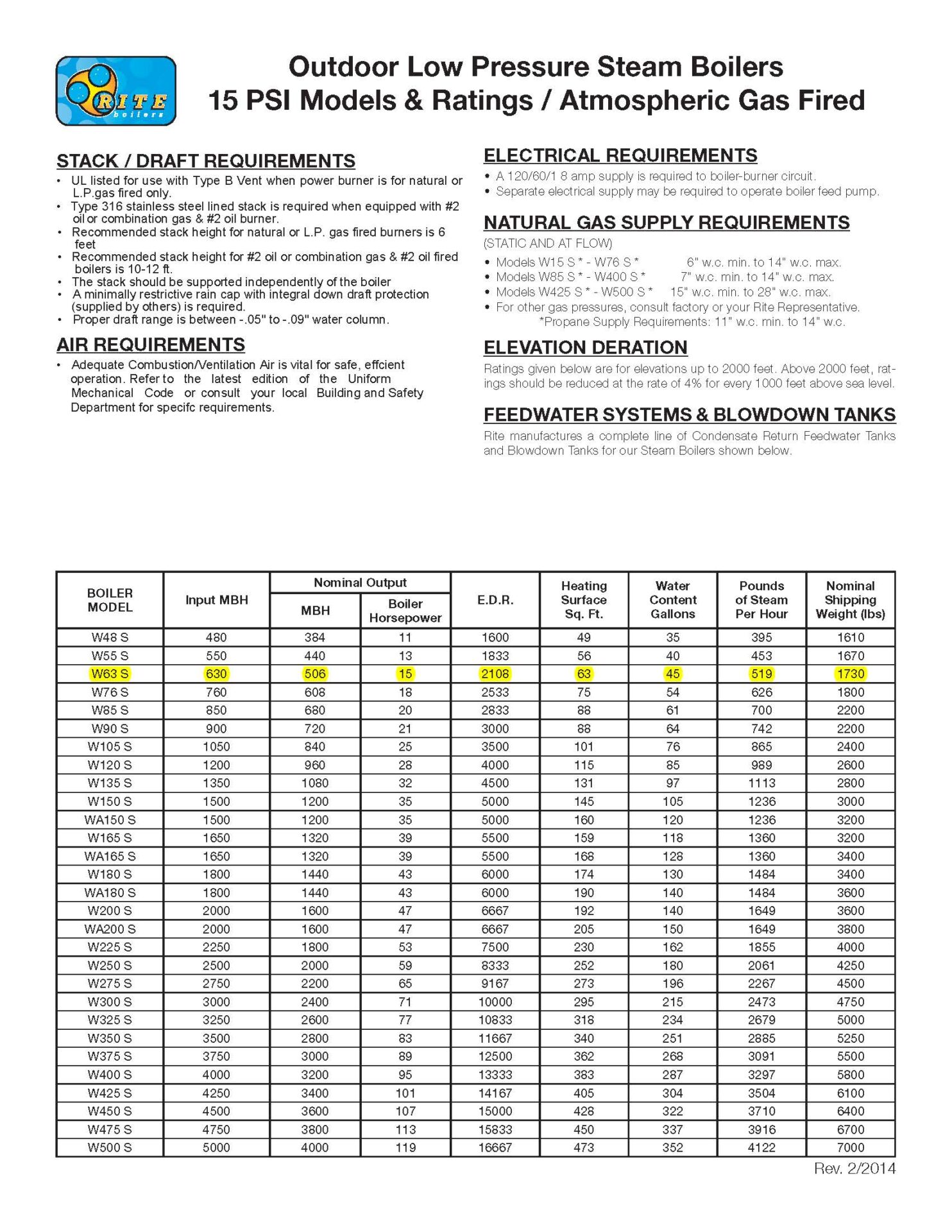

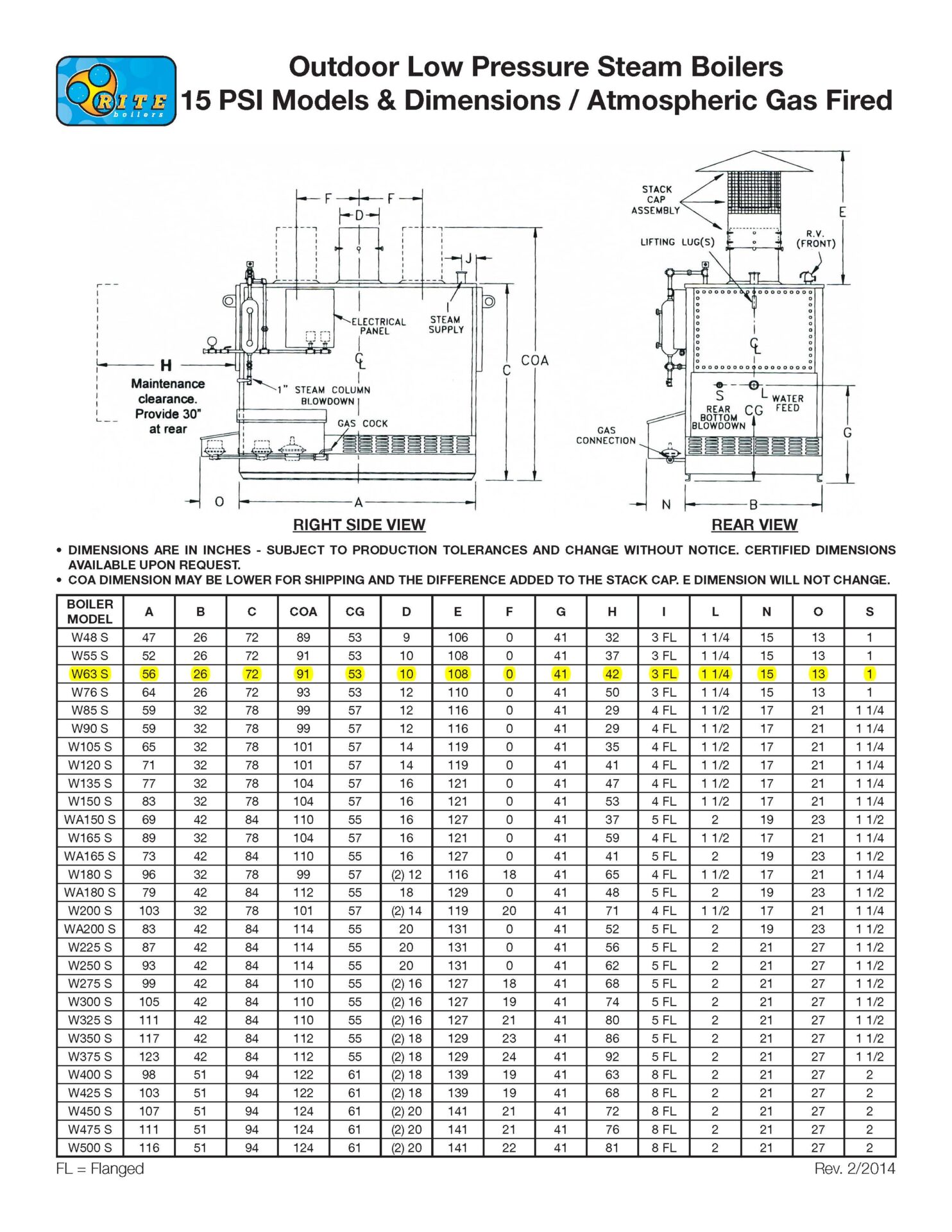

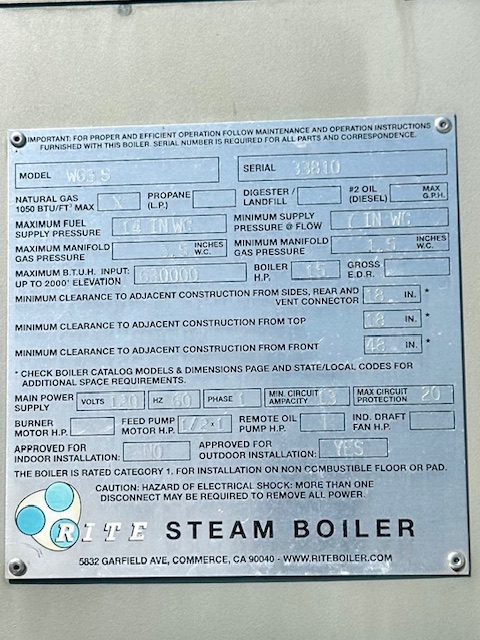

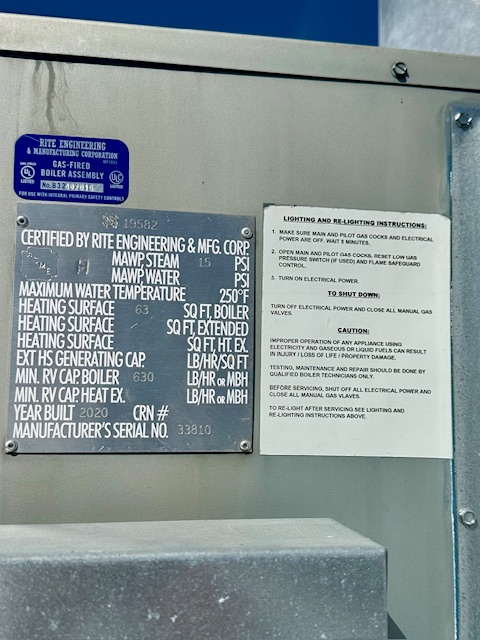

RITE OUTDOOR BOILER MODEL W63S LOW PRESS. STEAMATMOSPHERIC

- Rite Condensate Return Feedwater System Model CR-50 – Outdoor

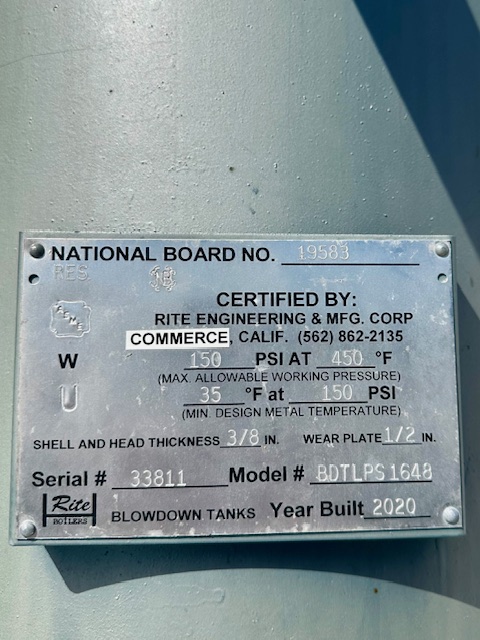

- Rite Blowdown Tank Model BDT-LPS1648

- United Brass Check Valve (2)

- Water Softener, Outdoor

- Chemical Feed System w/Sample Cooler

- Hoffman WC6-20B Condensate Transfer Pump

WILL SELL ITEMS INDIVIDUALLY – REACH OUT FOR PRICING.